At TFKable, innovation is the basis of our growth. Our research and development centres ensure that our products meet all national and international quality and safety standards, while incorporating the latest technological trends. As a result, our cables and wires have advanced performance characteristics that meet the expectations of the most demanding customers.

R&D Activities

To continually improve the quality and functionality of our products, we focus on

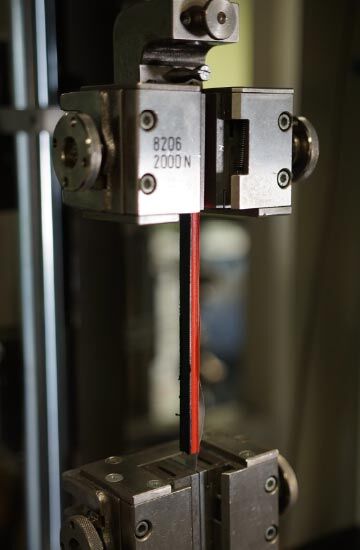

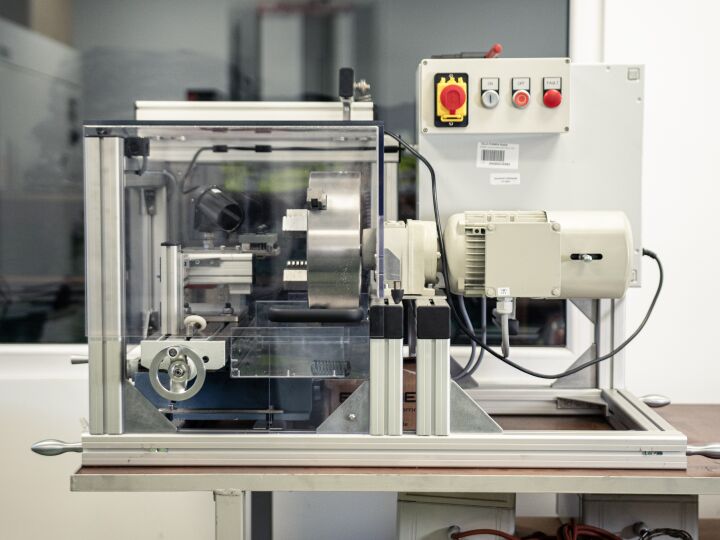

- Testing cables and wires to confirm their durability and reliability.

- Investment in advanced technologies, including modern control and measurement instruments and laboratory equipment.

Collaboration with universities and certification bodies, both nationally and internationally, enabling us to combine scientific knowledge with industrial practice.